3-axis Cam spring forming machine - Basic Type

CNC608, CNC620

spring machine with cams, spring former, wire forming machine, spring making machine, spring manufacturing machine

Cam spring forming machines are a cost-effective solution for mass production needs. They can be customized for specific applications, such as enameled wire (inductance) peeling and rolling, as well as special-shaped wire and sheet forming. With three axes - cam, feed, and wire-rotating, cam spring forming machines provide reliable and precise performance for all your spring manufacturing requirements.

Our cam spring forming machines are designed to meet the needs of customers with mass production requirements. Equipped with an 8-axis control card, our machines can easily add additional axes by purchasing related accessories in the future, providing a flexible and adaptable option. Additionally, our machines have shared bending tools between old and new models, reducing tool expenditures.

At Xinda, we take pride in our commitment to customer satisfaction. We provide comprehensive after-sales service to ensure that your machine stays in top condition and performs at its best. Our man-machine system software enables efficient adjustment lead times, optimized production efficiency, and spring accuracy, all with user-friendly operation.

Our cam spring forming machines are versatile and can produce a wide range of spring products, including tension springs, torsion springs, twin torsional springs, compression springs, battery springs, and flat wires. Our machines have demonstrated excellent performance, stable structure, and durability over time, with our first-generation machines still operating normally in many customers' factories for over 20 years.

If you are looking for a reliable and cost-effective solution for your spring manufacturing needs, Xinda's cam spring forming machine is the perfect choice. Contact us today to learn more about how we can help you.

Core Technology

- No matter testing or automatic production process, the machine's production speed and angle are the same, allowing the operator to better manage the accuracy and quality.

- Self-detection at startup for the status of driver, motor, software & hardware.

- Fill in the values of each axis to simply complete the program editing.

- All tooling holders can be fine-tuned. The minimum adjustment range can reach 0.01mm, making the adjustment of high-precision springs more convenient and accurate.

- Software program has undo and redo functions for easy editing.

- Built-in file management system: the program can be reused without rewriting when producing the same spring.

- USB port can import/export programs.

- Operating system can be upgraded via the USB port.

- The only waterproof keyboard used in the industry. The keyboard font is laser engraved which is durable and not blurred.

- Keys of the keyboard can be replaced individually.

Machine Features

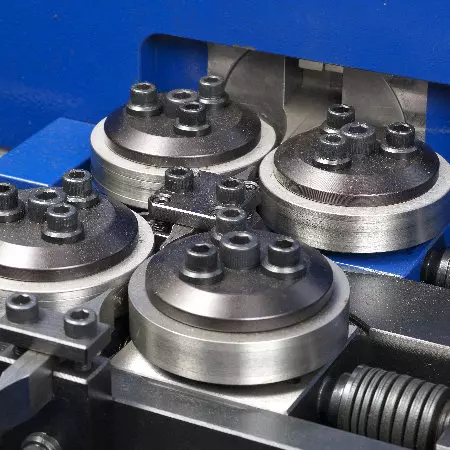

- Surface finish of the gear transmission system is grinding processed and the accuracy reaches DIN5 level.

- Special cams and reels can be customized to increase productivity.

- Cam transmission system uses a circulating lubrication mechanism to achieve the most ideal lubrication effect.

For CNC620:

- Can be customized as a specialized machine for enameled wire (inductance) peeling and rolling.

- Can be customized as a specialized machine for flat wire.

- Servo slide is made of high-strength, wear-resistant materials to achieve high rigidity and high load capacity.

Optional Equipment

- Servo Spinner

- Servo Hook Station

- Servo Rotary Gripper

- Servo Cutter

- Laser Sensor

- Infrared Probe

- Vision Sensor

- Hand Wheel (MPG)

- CE Safety Cover

- Wire Set

- Pan slide

Basic Specification

| Model Number | CNC608 | CNC620 | |

|---|---|---|---|

| Forming Capability | Wire Diameter Range (mm) | 0.15-0.8 | 0.2-2.3 |

| Max. Outer Diameter (mm) | 16 | 40 | |

| Max. Leg Length (mm) | 30 | 60 | |

| Machine Dimension | Full Length (mm) | 850 | 840 |

| Full Width (mm) | 1480 | 1530 | |

| Full Height (mm) | 1570 | 1570 | |

| Weight (kg) | 800 | 650 | |

| Power Requirements | Power Supply (V/Hz) | 220-440V/3P 50/60Hz | 220-440V/3P 50/60Hz |

| Power (kW) | 2.35 | 6.2 | |

| Rated Current (A) | 6 | 16 | |

| Servo Axes | Standard | 3 | 3 |

| Maximum | 8 | 8 | |

| Air Pressure Interface | 8 Ports | ||

| External Storage | USB | ||

| Ambient Temperature | 0 - 45°C | ||

Servo Specification

| Model Number | CNC608 | CNC620 | |

|---|---|---|---|

| Cam Movement Value | Min. | 1 | 1 |

| Max. | 4000 | 4000 | |

| Max. Speed (rpm) | 100 | 100 | |

| Wire Feed | Min. Increment (mm) | 0.01 | 0.01 |

| Max. Speed (m/min.) | 120 | 90 | |

| Quill Rotating | Min. Increment | 0.1° | 0.1° |

| Max. Speed (rpm) | 500 | 500 | |

* Note: All specifications and features are subject to change without notice.

- Download

Cam Spring Machine Series Specifications

This document provides the specifications for Xinda's cam spring machine series, allowing you to quickly understand the features, performance, and differences...

DownloadXinda Spring Machine Specifications Overview

This document compiles the detailed specifications of the entire Xinda spring machine series, helping you quickly understand the features, performance,...

DownloadSpring Machine Catalog: Professional Solutions for Boosting Spring Production Efficiency

Our Spring Machine Catalog offers comprehensive solutions to help you enhance spring production efficiency, improve quality, and reduce costs.

Download- Video

- Machine Details

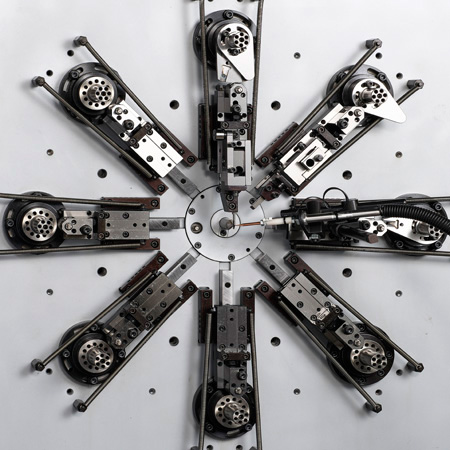

- Working Panel of the Cam Spring Forming Machine.

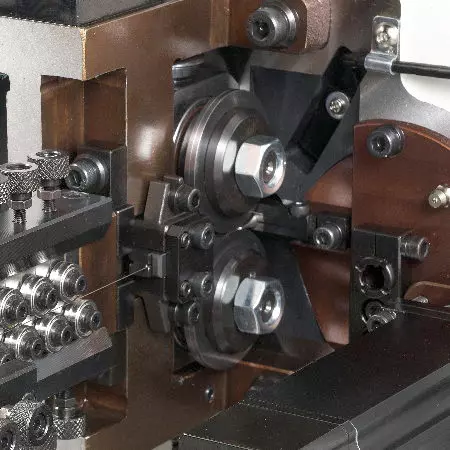

- Strengthening Set of the Cam Spring Forming Machine.

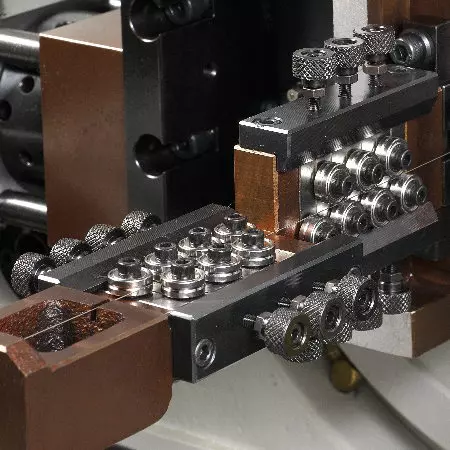

- Feed Set of the Cam spring forming machine .

- Rotary Gripper of the Cam spring forming machine.

- Rotary Quill Bender of the Cam spring forming machine.

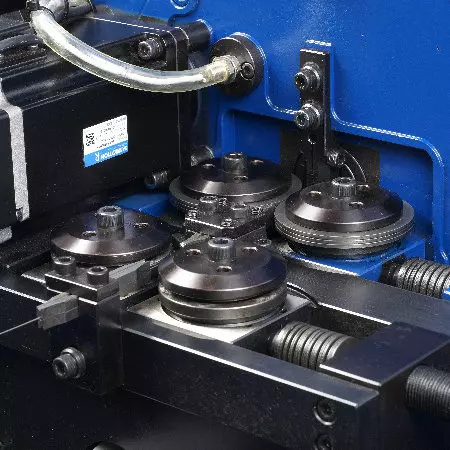

- Servo Cutting Set of the Cam Spring Former.

- Servo Spinner of the Cam Spring Former.

- Dual Servo Spinner of the Cam Spring Former.

- Servo Hook Station of the Cam Spring Forming Machine.

- 3-axis Feed Set of the Cam Spring Forming Machine.

- Flat Wire Feed Set of the Cam Spring Forming Machine.

- Spring Examples

- Torsion spring production planning proposal and spring forming machine.

- Torsion spring production planning proposal and spring forming machine.

- Sheet forming production planning proposal and spring forming machine with supplementary equipment.

- Sheet forming production planning proposal and spring forming machine with supplementary equipment.

- Sheet forming production planning proposal and spring forming machine with supplementary equipment.

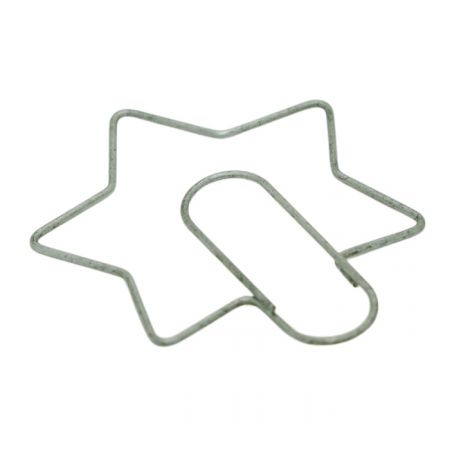

- Formed wire spring production planning proposal and spring forming machine.

- Formed wire spring production planning proposal and spring forming machine.

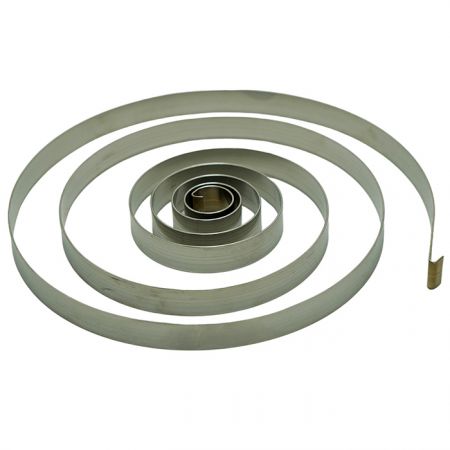

- Loop spring production planning proposal and spring forming machine.

- Carbon brush spring production planning proposal and spring forming machine.

- Standard tension spring production planning proposal and spring forming machine.

- Screw spring production planning proposal and spring forming machine.

- Related Products

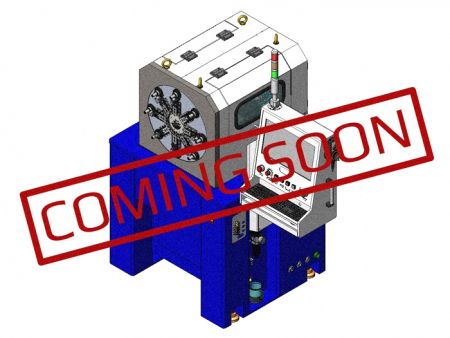

4-axis Cam spring forming machine - Wire-rotating Type

CNC620W, CNC635W, CNC650W

This spring forming machine is driven by a cam and equipped with the fundamental cam, feed,...

Details4-axis Cam spring forming machine - Bender-rotating Type

CNC405RT

To meet the demand for high precision thin wire springs, Xinda has developed a cam-driven spring...

Details

3-axis Cam spring forming machine - Basic Type | Comprehensive Solutions in Camless Spring Forming Machines for Industrial Buyers

Xinda Machine Co., Ltd., established in 1996 in Taiwan, leads in manufacturing spring and wire forming machinery. With a focus on innovation and quality, our product lineup includes 3-axis Cam spring forming machine - Basic Type, cam spring forming machinery, camless spring forming machines, patented X-type spring forming machines, specialized spring machines, wire forming machines. Xinda specializes in bespoke engineering, offering customized spring and wire forming machines tailored to meet unique industrial requirements. Our comprehensive approach covers design, development, and after-sales support, delivering precision-engineered solutions that enhance production capabilities.

Dedicated to revolutionizing spring manufacturing, Xinda has been at the forefront of providing advanced spring and wire forming machines since 1996. With an unwavering commitment to innovation and quality, we offer a comprehensive range of machines, including full-servo spring formers, universal multi-axis, camless and specialized spring forming solutions. Our state-of-the-art technology ensures unmatched precision, efficiency and reliability to meet the diverse needs of industries worldwide. Experience the future of spring manufacturing with Xinda's expertly engineered solutions - where excellence meets precision.

Xinda has been offering spring and wire forming machines since 1996, both with advanced spring forming technology and 40 years of experience, Xinda ensures each customer's demands are met.