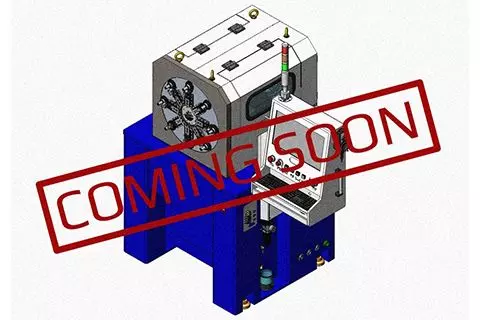

X-Type spring machine Helps a Research Institution Produce High-Precision & Complex Springs

The spring forming machine Team's Professional Capability and Attitude in Comprehensive Support Earn Praise from Customers

Xinda’s X-Type spring forming machine is an advanced solution that effectively addresses the challenges of spring manufacturing. It features variable stroke, wide range of evasion, strong forming ability, and meets both large-scale production requirements and small-batch customization demands. The machine can present various simulated arm modes, assisting the research institution in producing high-precision and complex springs.

Customer Background and Case Introduction

This is a case of a national-level research institution. During the R&D process, they needed various types of springs for their designs. However, traditional spring forming machines had insufficient production accuracy and couldn't meet their R&D needs, which hindered the project development. To solve this problem, the institution's engineers began to search for suitable spring manufacturers and eventually discovered Xinda's X-Type spring forming machine. This new type of spring forming machine can assist them in producing high-precision and high-difficulty springs, solving the spring problem during R&D and enabling smooth project development.

Thirdly, Xinda’s X-Type spring forming machine uses a lightweight wire feeder, which reduces inertia and improves the response speed, thus increasing production efficiency.

Lastly, the spring forming machine also has a probe compensation function, which can stabilize spring quality during production.

Overall, these features enable customers to easily produce high-precision and high-difficulty springs, and solve bottlenecks in project development.

Why the Customer Chose Us

The customer chose Xinda’s X-Type spring forming machine mainly due to the following advantages:

Firstly, the spring forming machine adopts testing and automatic production processes, which can ensure the consistency of the production speed and angle of the machine, making it easier for engineers to control precision and quality.

Secondly, the spring forming machine adopts a flat plate movement mode, which can control the initial tension of the spring and ensure the consistency and precision of the product.

Thirdly, Xinda’s X-Type spring forming machine uses a lightweight wire feeder, which reduces inertia and improves the response speed, thus increasing production efficiency.

Lastly, the spring forming machine also has a probe compensation function, which can stabilize spring quality during production.

Overall, these features enable customers to easily produce high-precision and high-difficulty springs, and solve bottlenecks in project development.

Customer Feedback

The engineers of the national-level research institution are very satisfied with the solutions and products provided by Xinda. They stated that Xinda’s X-Type spring forming machine not only meets their requirements for spring precision and customized production, but also allows them to conduct research and development more quickly, improve work efficiency, and save time and cost.

The variable stroke, wide avoidance range, and strong forming ability of this new type of spring forming machine allow them to produce high-difficulty and high-precision springs. The engineers of the institution particularly praised Xinda's team for their professional knowledge and technology, and stated that working with Xinda was a wise choice for them.

In addition, Xinda's team demonstrated a professional service attitude and dedication throughout the entire collaboration process. They provided comprehensive support and assistance to customers, solved the problems encountered by customers in the production and application process, and enabled customers to smoothly advance the project. Therefore, the national-level research institution will also recommend Xinda to other relevant institutions and companies.

In this case, Xinda not only successfully solved the customer's spring problem, but also demonstrated excellent professional knowledge and technology, and received high praise and recognition from the customer. This further enhances Xinda's influence and reputation in the spring market, injecting new power and vitality into the company's development.

- Related Products

11-axis X-Type spring forming machine

CNC10X, CNC25X, CNC42X, CNC60X

Xinda's X-Type Spring Former stands as a revolutionary innovation in the realm of spring manufacturing, empowering businesses to achieve unparalleled efficiency...

Details