After-Sales Service

Excellent after-sales service ensures smooth operation of your spring machine

Xinda provides comprehensive after-sales service for spring machines, including maintenance and training, to ensure the smooth operation of our customers' machines. The maintenance service is a comprehensive machine inspection and maintenance service aimed at ensuring the good operational condition of the spring machine and preventing potential malfunctions. Through regular maintenance service, you can ensure stable machine operation, minimize production interruptions, and losses. The training service provides professional training and guidance to help customers fully understand and utilize our spring machines. Through the training service, customers can effectively utilize the machine, maximize its performance and benefits, and improve production efficiency and product quality.

We are committed to providing comprehensive and professional after-sales service to ensure customer satisfaction and long-term operation of the spring machine. Whether it's maintenance service or training service, we strive to provide excellent support and solutions to our customers, ensuring they achieve optimal results and value when using our spring machines.

- Machine's Maintenance Service

Prevent Downtime Nightmares with Xinda's Spring Forming Machine Maintenance Service

Have you experienced the nightmare of a spring forming machine downtime? Every time an order comes in, production plans are already in place, but unexpected situations always arise. Questions like "Will the spring forming machine suddenly stop?" or "Can emergency repairs be made in time?" and "Do we have sufficient stock of consumable parts?" may haunt you. Sudden downtime not only incurs expensive emergency repair costs but also presents challenges in managing on-site personnel and maintaining planned production schedules, potentially damaging customer trust.

Let Xinda prepare you in advance during critical moments

The timing and specifics of unexpected situations are unpredictable, so it's crucial to be proactive and minimize losses. The Xinda team provides comprehensive spring forming machine maintenance service, conducting machine maintenance and upkeep in advance to ensure you don't miss any opportunities during critical times. Through regular maintenance, lubrication, critical structural checks, consumable replacements, anomaly analysis, and other measures, we address maintenance at the source, effectively avoiding unplanned downtime and the associated losses.

To illustrate with a simple example, when a belt ages or wears excessively without timely replacement, it may eventually lead to belt failure, resulting in a complete halt of the spring forming machine and affecting the golden production period. With Xinda's spring machine maintenance service, you can understand the machine's condition and maintenance methods, staying informed during every crucial moment. Please contact us and let our factory personnel assist you in keeping your machine in optimal condition.

Machine Maintenance Service Process

1. Schedule Appointment

- Taiwan: Reservations open every October, and Xinda will arrange the subsequent inspection schedule for you.

- Overseas: Prioritizing international exhibitions, open reservation dates will be notified irregularly.

2. Preliminary Assessment

Engineers conduct synchronous video diagnosis and analysis to ensure the preparation of materials and parts required for the inspection.

3. Quotation

Based on the preliminary assessment, we will discuss with the customer and provide a quotation. Once confirmed, the inspection schedule can be arranged.

4. Maintenance Check

On-site Maintenance: Our factory personnel perform inspections and parts replacements on-site. Overseas inspection will prioritize coordination with international exhibition schedules.

Distance-free Online Inspection

If on-site inspections are not feasible due to time, distance, or other factors, Xinda provides online inspection options:

- Synchronous Video Conferencing: Our factory personnel will prepare a similar machine as a demonstration and conduct two-way synchronous dismantling and inspection at the agreed-upon time, assisting you in conducting the inspection and safely replacing components.

- Instructional Videos: Xinda has produced a series of relevant videos, including machine operations, maintenance methods, and part replacements, to assist you in self-checking and part replacement.

With Xinda's spring forming machine maintenance service, you can effectively prevent the troubles of downtime, maintain smooth production, and ensure customer trust and satisfaction. Contact us now and let our professional team help you maintain your spring forming machine in optimal condition.

- Machine's Training Service

Comprehensive Machine Training Services: Making the Spring Forming Machine Your Ultimate Production Partner

After purchasing a new spring forming machine, you may wonder how to operate it smoothly, produce the springs your customers need, and handle any issues that may arise. Don't worry, Xinda is your spring machine expert, and we are here to find the answers together.

Quick Start, Precise Production, Professional Support - Xinda's machine training services ensure smooth production for you

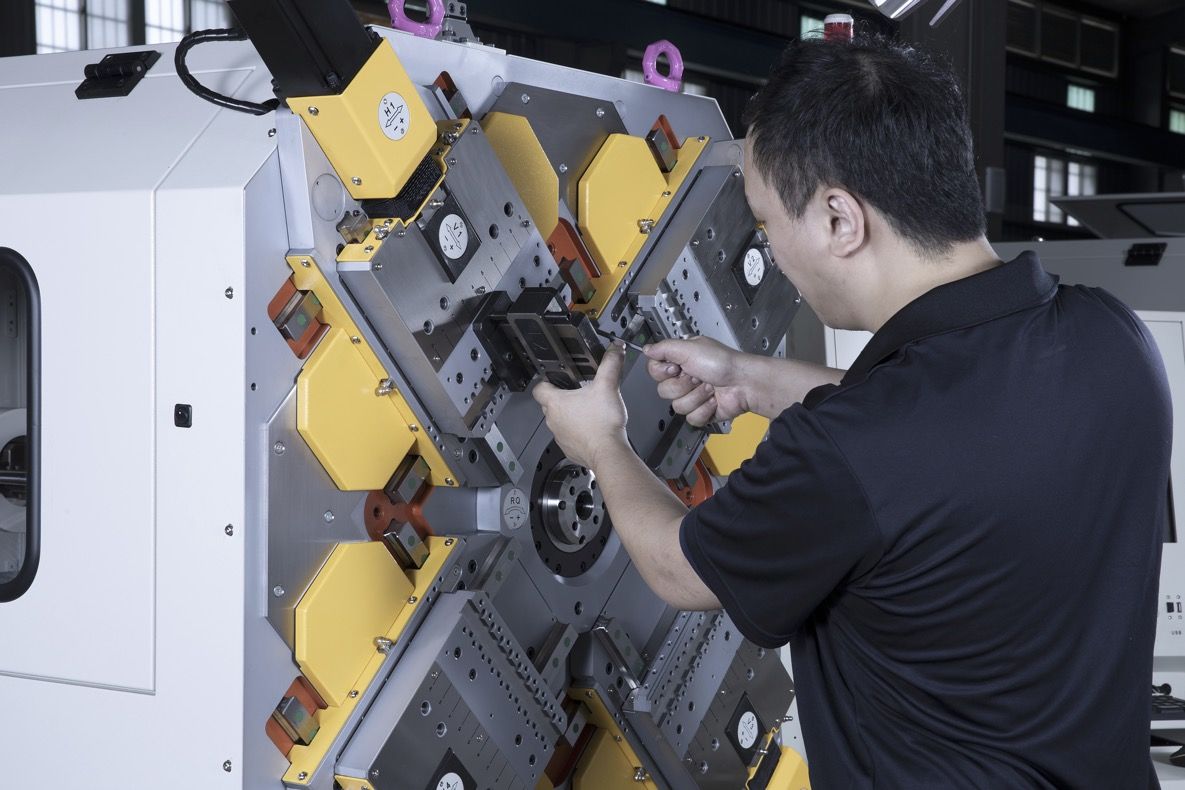

To help your new spring machine become a productive tool quickly and reduce the initial adjustment period, Xinda provides comprehensive machine training services. Our factory-trained technicians will provide you with guidance and demonstrations, helping you understand the different parts and functions of the spring machine and gradually familiarize yourself with the operating procedures. In addition to one-way instructional demonstrations, our technicians will also assist you in practical operations to ensure that you master the operation and maintenance of the spring machine.

With years of industry and customer experience, Xinda understands the various situations you may encounter during the adaptation period. Therefore, our designed machine training services aim to address your concerns and meet your expectations for capacity and spring products. We not only assist you in operating the spring machine but also help you with trial production and spring adjustments. Combined with post-consultations and follow-ups, we seamlessly integrate the spring machine into your production plan, making it your ultimate production partner.

Three Machine Training Service Modes: Providing the most suitable service based on your needs

Below are the three machine training service modes we have designed. We will provide the most suitable service based on your situation.

- Beginner's Course: Designed specifically for trainees who are new to the field, Xinda will arrange a series of courses for you. Our technicians will assist you in understanding the different parts and functions of the spring machine and provide instructional demonstrations to gradually familiarize you with the operating procedures.

- Guided Course: If you need to learn specific spring production techniques, Xinda will provide guidance on setting up and adjusting based on the springs you specify. Our technicians will explain each step in detail, guiding you through the process of fine-tuning the spring machine and maintaining spring stability.

- Advanced Course: Designed for customers who are already familiar with Xinda's spring machines, we offer advanced courses to provide in-depth knowledge of newly developed software or new features. Our technicians will provide explanations and practical demonstrations of the new software or features and assist you during hands-on operations. They will also provide appropriate suggestions for individual processing issues.

Machine Training Process

1. Needs Confirmation and Preparations: Through consultation forms, we confirm the model of the spring machine and the training content and make relevant preparations such as voltage, wire, attendees, and machine setup to ensure you have the best machine training experience.

- Beginner's Course: This course is designed for beginners and typically lasts for one to two weeks. The course covers basic operation instructions, explanation of machine parts and functions, wire alignment adjustment, tool utilization, installation and adjustment, as well as the use of peripheral equipment. We will also teach you how to set up single and double torsion springs and provide maintenance techniques for the spring machine.

- Guided Course: This is a tutorial course tailored to specific spring products. We provide guidance on setting up and adjusting based on the springs you specify. Our technicians will explain each step in detail, guiding you through the process of fine-tuning the spring machine and maintaining spring stability.

- Advanced Course: This course is designed for customers who are already familiar with Xinda's spring machines. We focus on the operation and practice of new software or features. Our technicians will provide explanations and demonstrations of the new features or software and provide assistance during your actual operations. We will also address individual processing issues and provide appropriate recommendations.

2.Machine Training Service: Based on your needs and choices, we offer beginner's courses, guided courses, and advanced courses.

3. Follow-up and Consultation: Within three months after completing the training, Xinda will reach out to you through phone calls, emails, or other communication methods to inquire about your usage status and confirm if you have any assistance needs. Additionally, if you have any questions, you can always contact Xinda directly.

Remote Training Video References

In addition to on-site machine training, Xinda also provides video references for remote learning and support. Over the past decades, Xinda has accumulated extensive experience in spring setups and recorded thousands of spring configuration methods in video format. Even if your personnel cannot be physically present, our videos can provide the support you need to a certain extent.

Since the introduction of our machine training services, Xinda has not only assisted customers in smoothly reducing the adjustment period of new machines and making the spring machine a productive tool but also successfully helped many second-generation successors seamlessly transition, transform, and expand their businesses. Additionally, we provide dedicated training accommodations to allow trainees to focus on learning without the inconvenience of travel. For Xinda, thinking from the customer's perspective is not just a slogan but a principle we embody through action.

We hope that through our three machine training service modes and remote training video references, you will be able to confidently master the operation skills of the spring machine, produce the required springs, and receive our assistance when facing challenges. Please feel free to contact us at any time. Xinda is delighted to provide you with professional machine training services, making your newly purchased spring machine your optimal production partner.