The spring forming machine with the timeline programming studio can reduce the idle time of the machine via the drag-and-shift function in the timeline mode, and greatly improve the production efficiency. The production speed can be higher than the traditional cam machine or the general camless machine in the market.

How does the software system of the spring forming machine help customers improve production efficiency?

Software and hardware together make the spring forming machine more efficient

The spring forming machine with timeline software can seamlessly integrate the movements of each axis. When the working axis is moving, other axes can also process at the same time without waiting time. In this way, the production efficiency of the spring forming machine can be greatly improved. The graphic user interface is intuitive and easy to use. The operator can simply reduce machine idle time by dragging idle time gaps in Timeline Mode. As long as the timeline is dragged in a consistent manner, the operation of the mechanism will be as smooth as a cam spring forming machine.

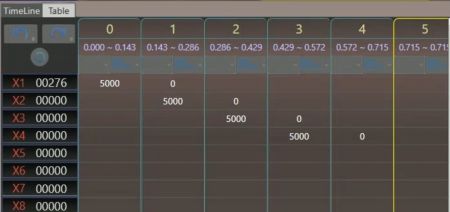

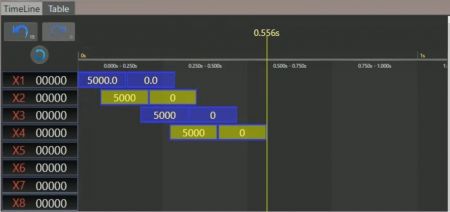

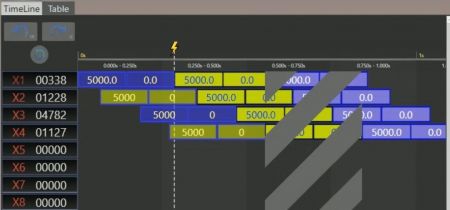

The following four illustrations are used to explain the working principle of the Timeline mode:

Before Using The Drag-And-Shift Function Of The Timeline Mode

After Using The Drag-And-Shift Function Of The Timeline Mode

Figure C shows that after using the drag-and-shift function of the Timeline mode, the idle time of the machine is shortened. The production speed can be increased to 32.4ppm, and the production efficiency is increased by 28%.

Figure D shows that in addition to using the drag-and-shift function, coupled with another flash function of the Timeline mode, the idle time of the machine can be shortened to almost zero. The production speed can be greatly increased to 63.0ppm, which is full 1.5 times improved compared to the production speed without using the timeline functions.

*Note: The above production speed is for reference only. The actual production rate will depend on the adjustment condition of the spring forming machine and the complexity of the spring.

The reason why Xinda's spring forming machine can increase the production speed is related to the programming of its unique Xinda's Programing Studio. As a result, customers can enjoy the benefits of increased productivity without having to adjust tool settings. In other words, customers can achieve a higher return on investment when purchasing a Xinda's camless or X-Type machine than other traditional camless machines in the market.

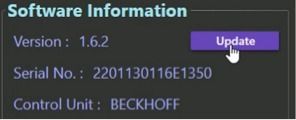

To meet customers' demands for faster, more precise and more complex spring production, Xinda's Programming Studio will keep pace with the times and continuously develop advanced functions. The new version of the software can be obtained by online download, and is provided to customers for free update. Xinda's Programming Studio is equipped on the camless and X-Type spring forming machines series.

To meet customers' demands for faster, more precise and more complex spring production, Xinda's Programming Studio will keep pace with the times and continuously develop advanced functions. The new version of the software can be obtained by online download, and is provided to customers for free update. Xinda's Programming Studio is equipped on the camless and X-Type machines series.

Xinda has accumulated rich experience in designing and manufacturing spring forming machines since the earliest two-axis cam spring forming machine era. We are happy to provide customers with a full range of spring forming machine solutions to help you solve any problems related to the production of springs.

- Related Case Study

-

X-Type spring machine Transforms the Spring Manufacturing Process for a Canadian Spring Factory

Xinda's X-Type spring forming machine is equipped with a streamlined slide design and exclusive timeline software that greatly simplifies the spring manufacturing...

Read more - Related Products

-

11-axis Camless spring forming machine - Wire-rotating Type

CNC1320W, CNC1350W, CNC1380W

The cam-free spring forming machine is a highly efficient full-servo spring forming machine...

Details11-axis X-Type spring forming machine

CNC10X, CNC25X, CNC42X, CNC60X

Xinda's X-Type Spring Former stands as a revolutionary innovation in the realm of spring manufacturing,...

Details