Cam Spring Forming Machinery

Affordable & High-Precision Cam Spring Machines:Trusted by Global Manufacturers

A cam spring machine is a traditional yet highly reliable spring coiling and forming machine that utilizes a cam-driven mechanism with digital control. In the past, complex spring shapes required additional manual mold adjustments for secondary processing. However, cam spring machines significantly reduce dependency on manual labor, making production more efficient.

Many experienced spring machine operators are familiar with the operation of cam-based systems, making them a preferred choice in the industry. Their affordable price and cost-efficiency also make them ideal for high-volume spring manufacturing.

A Legacy of Excellence in Cam Spring Machine Innovation

Since launching our first-generation cam spring machine (Model Number: CNC620) in 1997, Xinda has continuously evolved its product line to meet diverse wire diameter requirements. Our cam spring machines are not only economical but also highly stable, earning a reputation for their affordability, durability, and precision within the spring manufacturing industry.

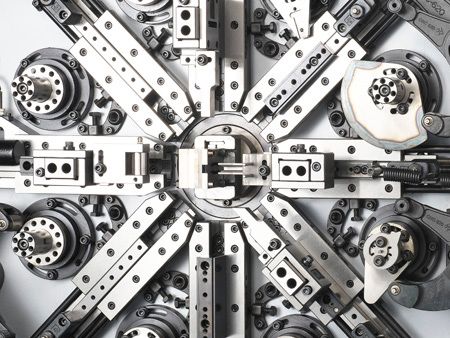

Designed with a coaxial cam-driven mechanism, the machine features eight forming arms, commonly referred to as a traditional cam machine, universal wire forming machine, or eight-arm cam machine.

Key Features of Our Cam Spring Forming Machines

• Compact footprint : Optimized for limited factory space

• High stability : Designed for consistent production output

• Precision engineering : Ensures accurate spring forming

• Long service life : Built for durability and continuous operation

• Low operational costs : Cost-effective investment for manufacturers

Basic and Rotary Wire Models to Meet Various Processing Needs

Our cam spring machines are categorized into two main types:

• Basic Model (3-Axis, expandable to 8-Axis)

• Rotary Wire Model (4-Axis, expandable to 8-Axis)

The rotary wire function allows the wire to rotate during forming, enabling flexible spring angle adjustments with a single tooling setup. This enhances ease of machine tuning while reducing production complexity, improving overall efficiency in custom spring manufacturing.

Trusted by Buyers Worldwide : High-Performance Cam Spring Machines

We specialize in manufacturing high-precision cam spring machines widely used in precision parts manufacturing, automation production lines, and mechanical industries. Our machines have been successfully sold to Taiwan, China, the U.S., Brazil, India, Thailand, Malaysia, Singapore, the Philippines, Vietnam, Turkey, Russia, Italy, Portugal, Slovenia, Slovakia, Croatia, Hungary, Switzerland, Japan, Mexico, South Korea, Poland, Indonesia, Bulgaria, and beyond.

Our machines are renowned for their stability, efficiency, durability, and customization flexibility, catering to a wide range of spring production needs worldwide. Whether you are looking to increase production capacity or enhance manufacturing precision, our cam spring machines offer the most suitable solution.

Contact Us Today for a Customized Quote & Technical Consultation

If you need a cam spring machine or have custom spring designs but are unsure about the right model, feel free to reach out. With over 30 years of experience, Xinda’s expert team is ready to provide professional advice and ensure you choose the most suitable spring machine for your manufacturing needs.

Optimize Your Spring Manufacturing – Get in Touch Now!

3-axis Cam spring forming machine - Basic Type

CNC608, CNC620

Cam spring forming machines are a cost-effective solution for mass production needs. They can be customized...

Details4-axis Cam spring forming machine - Wire-rotating Type

CNC620W, CNC635W, CNC650W

This spring forming machine is driven by a cam and equipped with the fundamental cam, feed,...

Details4-axis Cam spring forming machine - Bender-rotating Type

CNC405RT

To meet the demand for high precision thin wire springs, Xinda has developed a cam-driven spring...

DetailsCam Spring Forming Machinery | Unlock Efficiency with Xinda’s Patented X-type Spring Forming Technology

Xinda Machine Co., Ltd., established in 1996 in Taiwan, leads in manufacturing spring and wire forming machinery. With a focus on innovation and quality, our product lineup includes Cam Spring Forming Machinery, cam spring forming machinery, camless spring forming machines, patented X-type spring forming machines, specialized spring machines, wire forming machines. Xinda specializes in bespoke engineering, offering customized spring and wire forming machines tailored to meet unique industrial requirements. Our comprehensive approach covers design, development, and after-sales support, delivering precision-engineered solutions that enhance production capabilities.

Dedicated to revolutionizing spring manufacturing, Xinda has been at the forefront of providing advanced spring and wire forming machines since 1996. With an unwavering commitment to innovation and quality, we offer a comprehensive range of machines, including full-servo spring formers, universal multi-axis, camless and specialized spring forming solutions. Our state-of-the-art technology ensures unmatched precision, efficiency and reliability to meet the diverse needs of industries worldwide. Experience the future of spring manufacturing with Xinda's expertly engineered solutions - where excellence meets precision.

Xinda has been offering spring and wire forming machines since 1996, both with advanced spring forming technology and 40 years of experience, Xinda ensures each customer's demands are met.