The multi-axis spring forming machine is suitable for the forming of complex springs. The exclusively designed sofware can simplify and integrate redundant actions to increase the production capacity .

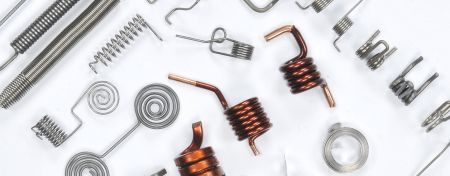

Which springs are suitable for production with multi-axis spring forming machines?

The "axis" in the spring forming machine is used to support the coupling transmission device between the various components, and the linkage device is driven by the servomotor to carry out the production operation. The number of axes is related to the precision, forming effect and processing efficiency of the spring forming machine.

The eight cams on the working panel of the 3-axis cam spring forming machine are all driven and controlled by one servomotor. Each bender can only form an angle in the single plane. Therefore, the forming function is limited. The machine tuning is relatively complicated. And, the ajustment of the cam phase requires experienced technicians.

The 4-axis cam spring forming machine is based on the 3-axis machine, with an added wire-rotating axis. The wire-rotating axis allows each bender no longer limited to a single plane, and able to form 3-dimension angles. The forming function is relatively strong, and more complex forming can be realized.

If the spring you want to produce has the following characteristics, a multi-axis camless spring forming machine is more suitable and recommneded:

1. Springs with smaller tolerances are required: Because each axis of the multi-axis machine is driven and controlled by an independent servomotor, each bender can advance and retreat with different strokes and speeds according to the program. The mechanical tolerance driven by the gear can be reduced. The finished product will also be more accurate.

2. Springs that are difficult to form: Some springs themselves require many different angles to complete. More axes make the forming function more flexible and powerful.

3. Springs with higher output are required: The multi-axis machine can greatly improve the production and processing efficiency because the equipment tuning is much easier.

Xinda's camless spring forming machines and X-Type spring forming machines are multi-axis formers that can achieve complex forming. The exclusively designed timeline function & Overlap Mode can simplify and integrate redundant actions, and even increase the production capacity by 2 ~ 3 times compared with the traditional cam machine in the manufacture of certain special springs.

- Related Case Study

Camless spring machine Boosts Production by 2 times for an Indian Factory

Xinda successfully helped a spring factory in central India solve production efficiency problems by providing the camless spring forming machine that meets...

Read more